Improving standard DPTE - text

Educated in the Control and Development of Pharmaceutical Products, Sophie Corbineau worked in pharmaceutical production for eight years, before joining Getinge as a Validation Expert in 2015.

As part of Getinge’s continuous development of sterile transfer solutions, our growing team of experts constantly work to improve every aspect of the original DPTE® system. One such specialist is Sophie Corbineau, Validation Engineer at Getinge’s manufacturing facility in Vendôme, France.

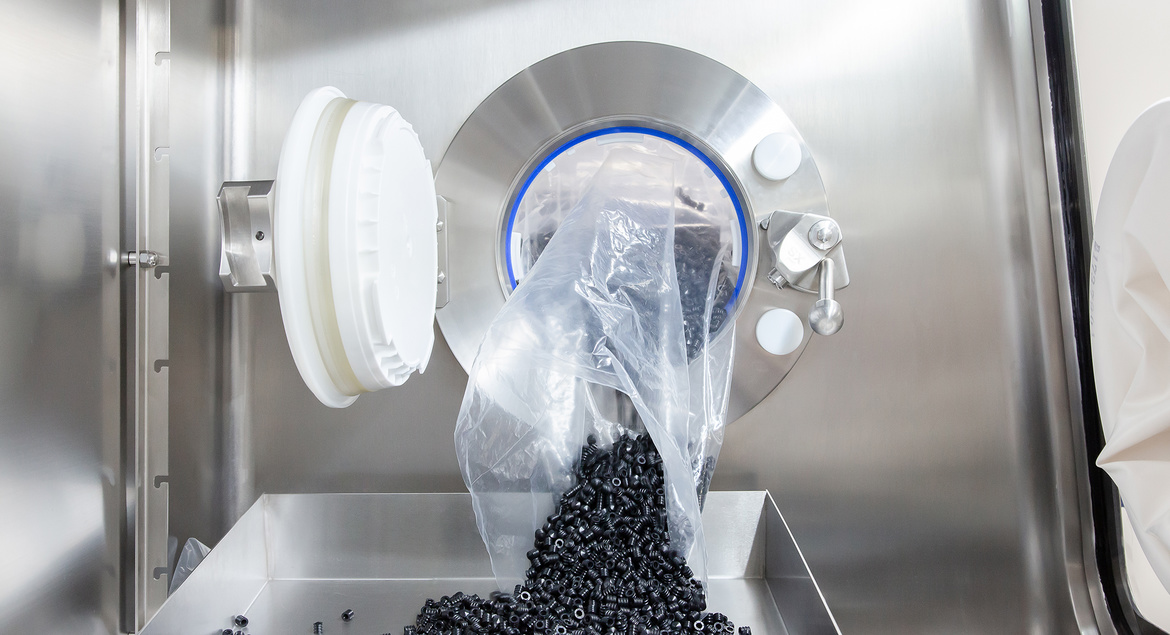

When the company made the decision to internalize production of parts for its DPTE-BetaBag® Tyvek® to the site in Vendôme, Sophie and the validation team organized installation and validation to ensure the necessary conditions for success.

Creating the proper environment

Getinge produces its DPTE-BetaBag® solutions in cleanroom environments certified to pharmaceutical standards ISO 5 and ISO 7. “During an installation, it’s critical to ensure that the cleanroom doors are kept closed as much as possible,” Sophie explains. “This is why we plan all changes to coincide with the site’s two-week summer production break, to minimize disruptions.”

During this time, the team not only installs new systems, but also conducts an annual analysis and cleaning of every aspect of the cleanrooms. “This is a huge task, because we test and validate the in-use equipment and the new equipment together, and everything has to be logged in the Validation Master Plan (VMP) database.”

The importance of VMP documentation

When working in a contamination-controlled environment, it’s critical to document every aspect of the production process, including the cleanrooms; the products themselves; document control; validation techniques; and much more. All of this information is contained within the VMP.

“The VMP is an extremely important document within the pharmaceutical industry,” Sophie explains. It helps to ensure that good manufacturing practice (GMP) is followed at all times. “Every time we follow a validation protocol, we log the people involved, the budgets, the number of the sample, everything,” she says. It not only allows Getinge to track and manage internal process controls, but also serves as a record of all processes in the case of an inspection or audit.

Increasing our offering through process innovation

Before joining Getinge, Sophie worked for eight years in a pharmaceutical laboratory. This background gave her a deep understanding of the complexities, checks, and documentation involved in production in a regulated environment. “Of course,” says Sophie, “in the end, this is to ensure high quality production to protect patient safety.”

Patient safety is the reason Getinge constantly strives to improve the quality of Beta components. “Since I began my career at Getinge, we’ve enhanced the validation process for the DPTE-BetaBag®, and we’ve made the VMP extremely strict on all our Beta products,” says Sophie. “This process of continuous development is very important for us, so we can improve outcomes for our customers.”

Looking ahead

In the future, Sophie sees Getinge expanding to offer customers even more possibilities. As part of an ongoing process of innovation, the Getinge team is always looking for ways to improve every aspect of their DPTE-BetaBag® offering. Sophie gives us an insight into “the BetaBag of the future” – making the bags even cleaner, more leaktight, longer-lasting, and more sustainable and eco-friendly, such as finding ways to test the bags without using ammonia.

“I look forward to creating more products that don’t just meet the market’s changing needs, but exceed them – while maintaining the highest possible level of quality,” she says. “Tomorrow, who knows what we’ll be able to offer?”