- Overview

- Features

- Applications

- Accessories

- Documents

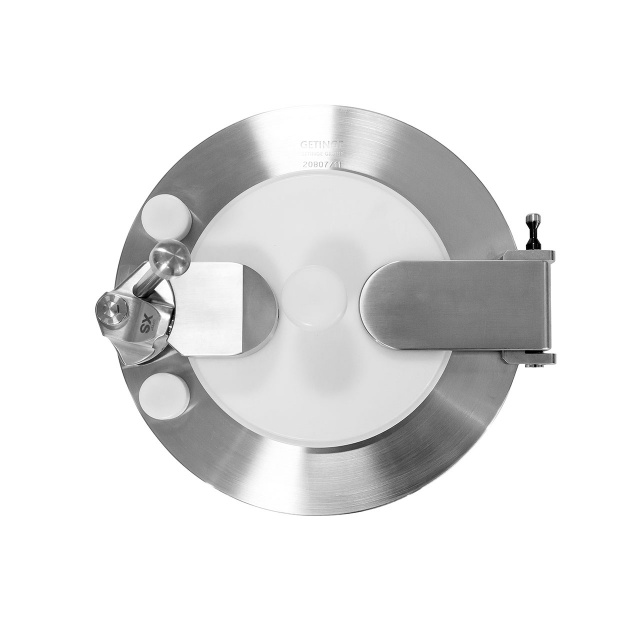

DPTE®-XS Alpha Port

The benchmark for sterile transfer

With more than 40,000 DPTE®-XS Alpha units installed worldwide, its reliability and safety have set it as the industry standard.

- Leak tight transfer

- Reliable and safe transfer

- Total solution with Beta parts and accessories

- Validated solution

- A large variety of applications

The original rapid transfer port (RTP)

When it comes to securing aseptic transfer, only the original DPTE® system from Getinge gives you the confidence you want and the quality you need.

DPTE® brings you the highest level of production and patient safety, a flexible and cost-effective process along with the assurance of rigorous validation and reliable expert support.

Getinge develops, manufactures, and supports complete RTP solutions:

- DPTE®-XS and DPTE®-EXO Alpha ports

- Single-use DPTE-BetaBag® and reusable DPTE® Beta Containers

- DPTE® Transfer Trolley for both bags and containers

- DPTE® Transfer Leak Testers (TLT)

Watch the video to view the DPTE® System used in the fill-finish process.

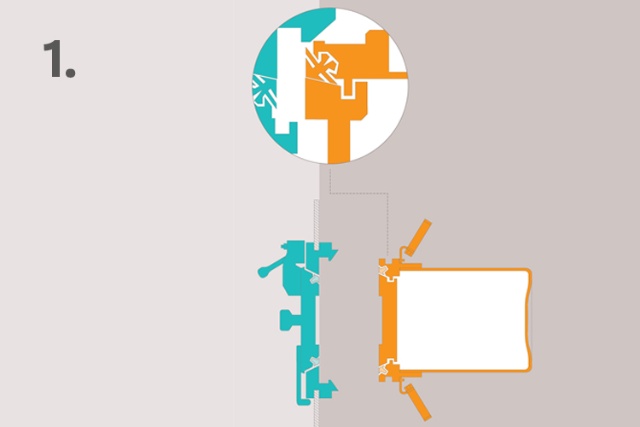

How does the DPTE®-XS system work?

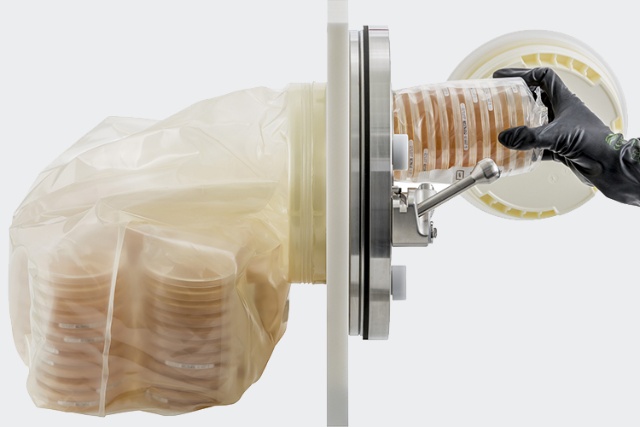

1. Line up the DPTE®-XS Alpha and Beta parts

The Alpha part is mounted on a support – commonly an isolator, RABS, BSC, or cleanroom.

The Beta part consists of a container, bag, or other Beta device used for the transfer of components, solids, or liquids.

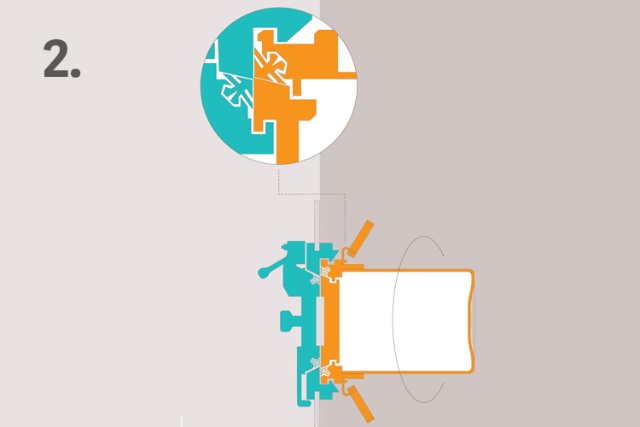

2. Rotate the Beta part 60° to ensure leak tight seal

The Alpha parts and Beta parts are connected by a manual 60° rotation which detached the doors from their supports and joins them together.

Tightness is secured by the lip seals of the new assembly.

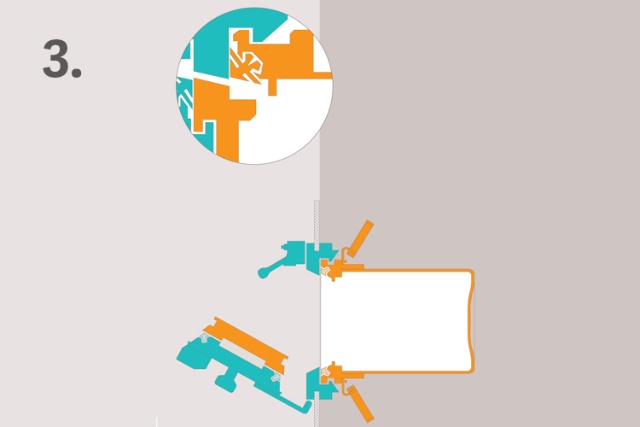

3. Open the doors without breaking sterility or containment

The doors can now be opened without breaking sterility or containment.

The combination of DPTE® Alpha and DPTE® Beta parts is a validated solution. Used together, they provide highly secure transfer and protect your production.

Related products

Leak-Tight Transfer

Once connected, the Alpha and Beta components join together to form a single unit.

The DPTE® Alpha/Beta's safety interlocks and lip seals ensure reliable and leak-tight transfer. The assembly supports the safety of users and patients by minimizing the risk of contamination, and ensuring the DPTE® system can be opened without breaking sterility or containment.

Ultra-Safe Transfer

The core of the DPTE® system is the Alpha port with its secure interlock enabling totally safe connections and disconnections. Simple and easy to use, it minimizes the risk of contamination.

- The operator cannot open the DPTE® Alpha door when the DPTE® Beta part is not properly connected.

- The operator cannot disconnect the DPTE® Beta part if the double door is not closed.

- The operator cannot open the DPTE® Alpha door when the DPTE® Beta port is not equipped with the Beta part.

Validated Solution

Fully validated, the DPTE® Alpha and DPTE® Beta equipment work perfectly together to greatly improve process efficiency and avoid contamination risk.

Installing a complete DPTE® system removes the need to invest your resources and time in attempting to validate a unique combination of Alpha and Beta parts, which means a sizeable reduction in the overall project cost.

Match your DPTE® Alpha port with the right Beta part from Getinge to guarantee your product and/or operator safety.

DPTE®-XS Alpha Port Specifications

Diameter |

105 mm |

190 mm |

270 mm |

350 mm |

460 mm |

Useful Diameter |

95 mm | 170 mm | 250 mm | 330 mm | 440 mm |

Available Lip Seal |

|

|

|

|

|

Many applications

Validated to comply with international regulations, the DPTE® System

is used in various applications in aseptic and contained production.

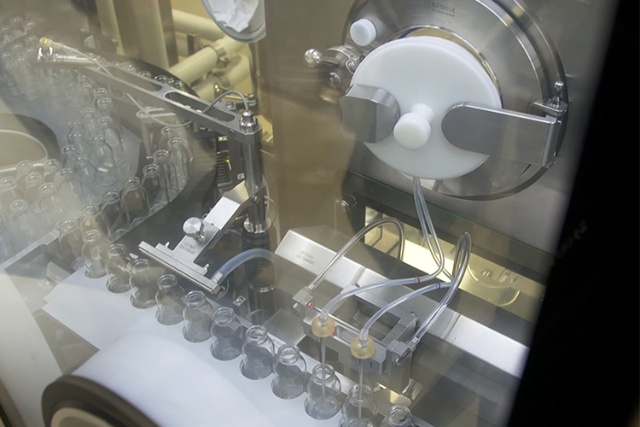

Liquid Transfer

Component Transfer

Environmental Monitoring

Machine Parts

Waste Disposal

And many more...

Marketing Sales - Brochures

-

The original Rapid Transfer Port