- Overview

- Features

- Applications

- Documents

Applikon BioBench

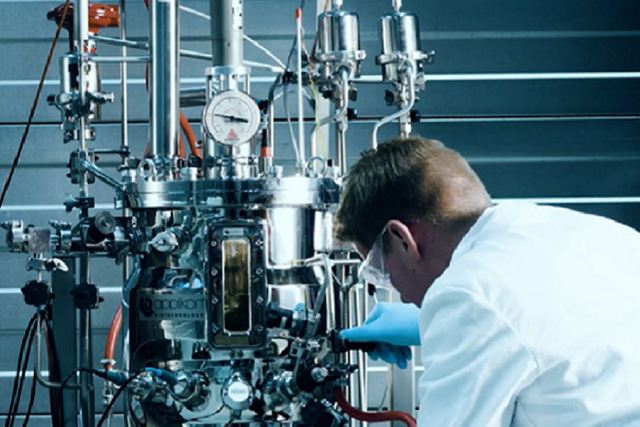

The workhorse in your process development

- Compact design reduces floor space needed

- cGMP compliant design simplifies validation

- Modular design allows easy configuration to match process demands

- Worry-free operation; no punctured bags, no leaking of tubes and connectors

Essential in developing vaccines and medicines

Bioreactors play a key role in developing and producing life-saving vaccines and medicines. This complex process requires highly optimized, state of the art systems. With the Applikon BioBench standardized bioreactor designs, we provide ease and flexibility of customizing the vessel to handle any type of application needs with standard components.

Watch the video to view the stainless steel bioreactors being used in bioprocesses.

Easy to validate

The BioBench range is built to the latest standards on hygienic processing, meeting cGMP and GAMP requirements, and can be supplied with an extensive documentation package to support efficient validation.

Easy to operate

Stainless steel bioreactors minimizes the risk of contamination as there are no consumables to be replaced for every single run. Furthermore, these Sterilizable-in-Place bioreactors are supplied with magnetic coupled agitator connections, instead of traditional connections (lipsealed or double mechanical seal). Since there is no connection with the outside world, there is no risk of contamination.

The open frame construction gives easy access for maintenance and operation.

Easy to clean

The Applikon stainless steel bioreactor range is completely fabricated using pharma-grade 316L stainless steel and supplied with a surface finish of Ra < 0.4 micron. This smooth surface ensures that biofilms and debris will not stick to the internals of the bioreactors. This greatly simplifies the cleaning procedure and creates ease of mind knowing that the bioreactors will always be reproducible clean.

Specifications

| Total volume(liter) | Working volume(liter) | Minimum working volume(liter) | Aspect ratio total volume | Aspect ratio working volume | |

| 15 liter Bio Bench | 15 | 12 | 4 | 2.2 | 1.7 |

| 20 liter Bio Bench | 20 | 17 | 4 | 3.0 | 2.4 |

| 30 liter Bio Bench | 30 | 22 | 7 | 2.0 | 1.6 |

| Drive system | Magnetically coupled, top mounted agitator for microbial cultures and top mounted for cell culture systems | ||||

| Maximum agitator tipspeed (m/s) | 5 m/s for microbial cultures and 1 m/s for cell cultures | ||||

| Impellers | Rushton and marine with outside diameters 0.3 - 0.5 vessel diameter | ||||

| Gas sparger | Porous sparger or L-Sparger | ||||

| Gas overlay | Gas overlay line | ||||

| Exhaust gas | Water cooled exhaust gas condenser with internal spiral and/or jacketed | ||||

| Sampling | Optional resterilizable sample system in DN25 port in lower side wall | ||||

| Draining | Resterilizable bottom mounted bellows drain | ||||

| Additions | Sterilizable additions (push valves) and resterilizable addition ports | ||||

| pH | Measurement: 12 mm classic pH sensor in DN25 port in lower side wall | ||||

| Control: via acid pump or CO2 gas (rotameter or MFC) in combination with alkali pump | |||||

| DO2 | Measurement: 12 mm polarographic DO2 sensor in DN25 port in lower side wall | ||||

| Control: via a combination of N2, Air, O2 (Rotameter or MFC) and agitation | |||||

| Temperature | Measurement: Pt-100 sensor in DN25 port in lower side wall | ||||

| Cultivation control: cooling and heating jacket via bioreactor wall | |||||

| Foam | Measurement: Height adjustable conductivity based foam sensor | ||||

| Control: via antifoam pump | |||||

| Level | Measurement: Height adjustable conductivity based level sensor | ||||

| Control: pump for liquid addition or removal | |||||

The Applikon BioBench is ideal for the following applications:

- Scale-up studies

- Medium optimization

- Process optimization

- Small scale production

- Seed train

- Microbial and cell culture

- Batch, Fed-Batch, Perfusion and Continuous cultivation

Marketing Sales - Brochures

-

Stainless steel bioreactors for biopharmaceutical development and production